Manufacture of Special Vehicles

A special vehicle is personal and unique. RLA works to make it so. For this, it has an integrated production system and a team of multidisciplinary engineers and professionals who develop unique and innovative solutions in the shortest possible time and with the best levels of quality and reliability.

Each client demands a type of vehicle adapted to their own needs, which vary depending on their region or country and the conditions in which they must provide the service. RLA has developed a manufacturing structure based on Vertical Integration of most of its processes, mainly those aimed at differentiating the product and creating greater added value for the customer.

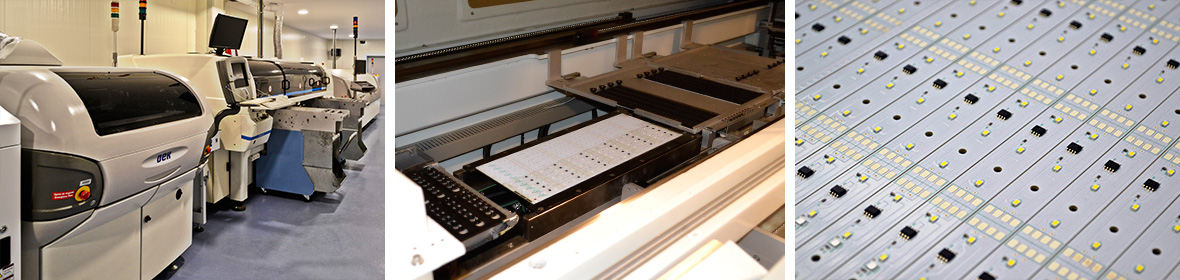

The facilities are designed to achieve the required flexibility, production capacity, quality and customization goals. It has machinery for plastic extrusion, thermoforming, laser, milling machines, lathes, folding machines, profiling machines, CNC cutting, automated painting lines and the manufacture of electronic plates, which are progressively increased with the incorporation of new industrial processes according to needs. of the market and the demands of our clients.

Aerial view

Infrastructure

Total Area (m2)

Conditioned Warehouses (m2)

Offices (m2)

Average Annual Workforce